Call Us Now:+8613867129219

Carbon Steel Wire Drawing Machine

Product Details:

- Application Industrial

- Product Type Carbon Steel Wire Drawing Machine

- Wire Material Copper Wire

- Condition New

- Click to view more

X

Carbon Steel Wire Drawing Machine Price And Quantity

- 1 Unit

Carbon Steel Wire Drawing Machine Product Specifications

- Carbon Steel Wire Drawing Machine

- Industrial

- New

- Copper Wire

Carbon Steel Wire Drawing Machine Trade Information

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID)

- 3-4 Week

- Australia North America Eastern Europe South America Western Europe Central America Middle East Asia

- All India

- CE Certificate

Product Description

Straight line wire drawing machine for high, middle, low carbon steel

For GI wire, spring wire, nail wire, mesh wire, binding wire, CO2 welding wire, tyre wire etc.

Technical data:

- Draw No. 7

- Meterial to treat: low, mild, high carbon steel

- Meterial strength: 1250Mpa

- Inlet Dia.:5.5mm-6.5mm

- Outlet Dia.:1.8mm-2.5mm

- Max. total compressibility: 88%

- Max. drawing force: 7000N

- Traction: asynchronours motor with inverter control

- Input by touch screen

- Total power: 30KW+22KWX6+18.5KW

- Size: 9650x2000x2400mm

- Speed: 10m/s

- Output: 18.5MT/per day/ for Dia. 2.0mm wire(880KG per hour)

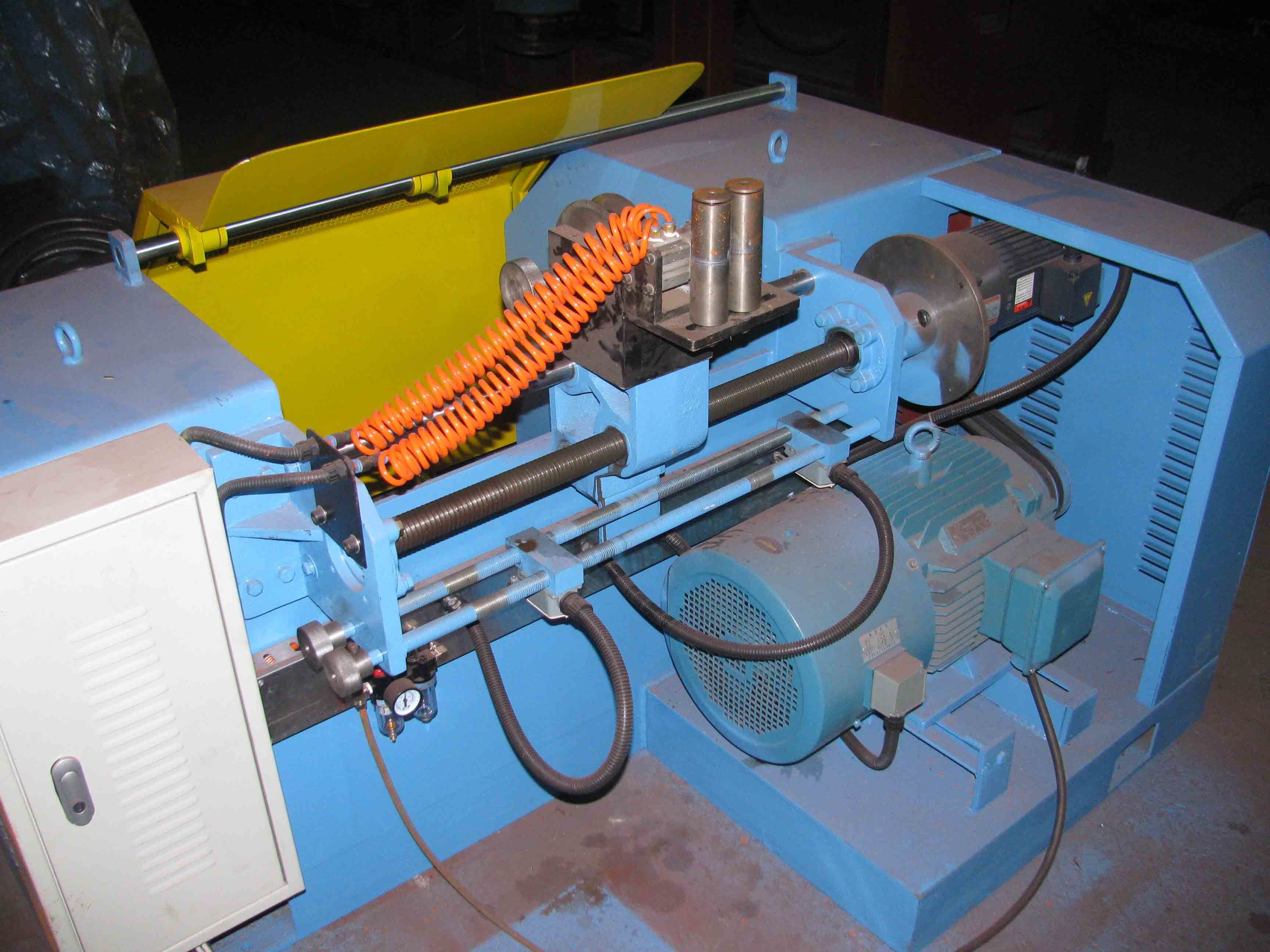

- A. The first motor is 30KW power, and the next six motors are with 22KW power,

- The type of first draw: wire-accumulating type. While feeding the material, the next blocks still remain working.

- The next six drawing be straight line drawing.

- Blocks NO.1-4 are driven by gearbox, and blocks NO.5-7 are driven by two class belt.

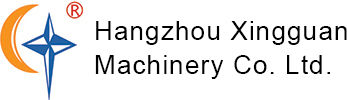

The first die: rotation die.

- The machine frame is made of steel square pipe and armor plate. Four capstan (head) are composed on one frames, so there are two frames for twelve capstans, it is with good integrity.

- The cooling system for capstan: fan cooling plus water cooling combination.

- The cooling for dies: compulsory water cooling.

- The pneumatic system is used for the spool loading and unloading.

- Safety stop and wire break protection are adopted so as to improve the security for operators.

Configuration

- Motors with inverter control.

- Inverter be high performance vector type inverter with brand of YASKAWA

- Relay: PANASONIC product

- Proximity switches: OMRON product

- Analog output proximity switches be CONTRINEX, SWISS

- Main shaft bearing: NSK.

- PLC control system: SIEMENS

- Touch screen input: SIEMENS

- Cables at site provided by buyer

- All rotation parts that touches with wire are coated with Tustgen-carbid, with hardness more than HRC58.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese